Nylon Stretch: A Detailed Exploration of Its Features and Applications

Nylon stretch is a revolutionary material that stands as a pillar in many industries. Renowned for its elasticity and robustness, it is employed in a multitude of areas, offering unmatched performance and reliability. Below, we explore its properties, technical aspects, and extensive use cases.

Unparalleled Characteristics of Nylon Stretch

- Elasticity and Flexibility: Nylon stretch showcases remarkable flexibility, allowing it to expand and contract without losing its form, which makes it a vital component in applications requiring dynamic movement.

- Durability: Resistant to wear and tear, it outlasts many other materials under continuous use, ensuring longevity.

- Lightweight Composition: Despite its strength, it remains light, making it ideal for a variety of applications.

- Chemical Resistance: Resistant to oil, grease, and many other chemicals, which extends its usability in specialized sectors.

- Thermal Stability: Exhibits excellent performance in varied temperature ranges, making it adaptable for both hot and cold conditions.

Broad Spectrum of Applications

Nylon stretch finds its place in a vast array of industries due to its unique attributes:

- Textile Industry: A cornerstone in the production of leggings, tights, activewear, swimwear, and hosiery, ensuring both comfort and durability.

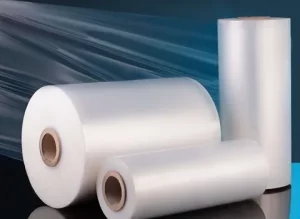

- Packaging Sector: Used in stretch films that secure goods during transportation and storage, minimizing risks of damage.

- Medical Field: Integral in the production of bandages, braces, and compression garments, providing support and flexibility for patients.

- Sports Equipment: Found in high-performance gear such as gloves, flexible padding, and sportswear to maximize functionality.

- Automotive Industry: Utilized for seat covers, upholstery, and airbag components, ensuring both safety and comfort.

- Agriculture: Applied in protective coverings for crops, greenhouse materials, and plant-support nets.

Technological Processes in Production

The manufacturing of nylon stretch involves several steps designed to enhance its unique properties:

- Polymerization: The base material is synthesized through controlled chemical reactions.

- Stretching and Spinning: Advanced techniques ensure uniformity in elasticity and structural integrity during the production process.

- Quality Control: Ensures consistency and adherence to industrial standards to meet diverse requirements.

Future Prospects of Nylon Stretch

Nylon stretch continues to evolve, with researchers focusing on innovations to expand its utility:

- Smart Textiles: Integration with sensors for health monitoring or temperature regulation.

- Advanced Packaging Solutions: Improved flexibility and strength for emerging demands in logistics.

- Eco-Friendly Enhancements: Research into sustainable production methods to align with global environmental goals.

Buy Nylon Stretchfrom GranulePlust Company:

Since we are a granule polyethylene manufacturer, we can produce the polyethylene you need in the form of compounds and granules in the desired grade and with the quality approved by you.

You can contact the sales manager of the company .

phone:+989196499881

email: info@granuleplast.com